Rerefined Oil

California drivers have more sustainable alternative to virgin motor oil – rerefined motor oil:

- Test after test shows re-refined oil is as good, if not better, than virgin oil.

- American Petroleum Institute (API)-certified Rerefined lubricants comply fully with vehicle manufacturers’ warranty requirements.

- Rerefining is more energy-efficient and less harmful way to manage used oil.

Lubricating oil does not wear out. It simply gets dirty as it works. Just removing water and contaminants makes a rerefined base oil of equal quality.

Rerefined oil products have the same stringent refining, compounding, and performance standards as virgin oil products.

API-licensed re-refined oils must pass the same cold-start, pumpability, rust-corrosion, engine-wear, and high-temperature viscosity tests that virgin oils do.

The API and American Automobile Manufacturers Association have developed the Engine Oil Licensing Certification System to ensure all engine oils consistently meet performance specifications.

What is Rerefined Oil?

- Used motor oil is processed to remove contaminants, producing a like-new base oil.

- Substances are added to make lubricants like motor oil, transmission fluid, and grease.

- The main difference is rerefined products cause less environmental harm than virgin oil products.

Are Rerefined Lubricants Safe to Use?

- Some vehicle and engine manufacturers issue warranties for rerefined oil to meet API standards.

- Users report no difference in vehicle performance with rerefined lubricants.

- Major oil companies often use rerefined base stock for their own rerefined oil brand.

Why Use Rerefined Oil?

- It reduces:

- Dependence on imported oil

- The depletion of natural resources.

- It conserves:

- Nonrenewable oil resources

- The environment

How is Oil Rerefined?

Base oils are first cleansed of contaminants, then hydrotreated to remove remaining chemicals.

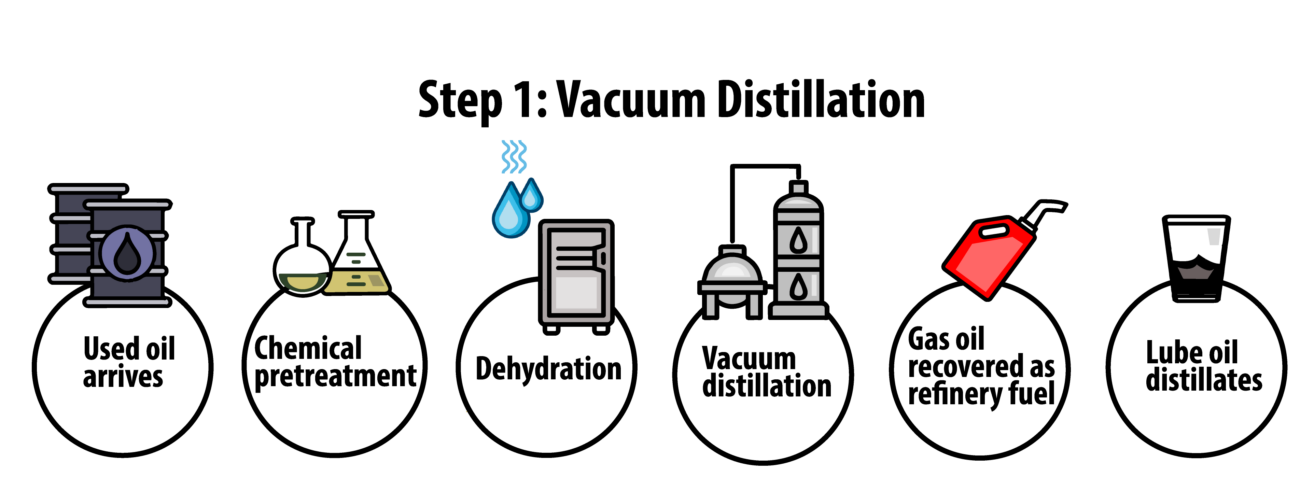

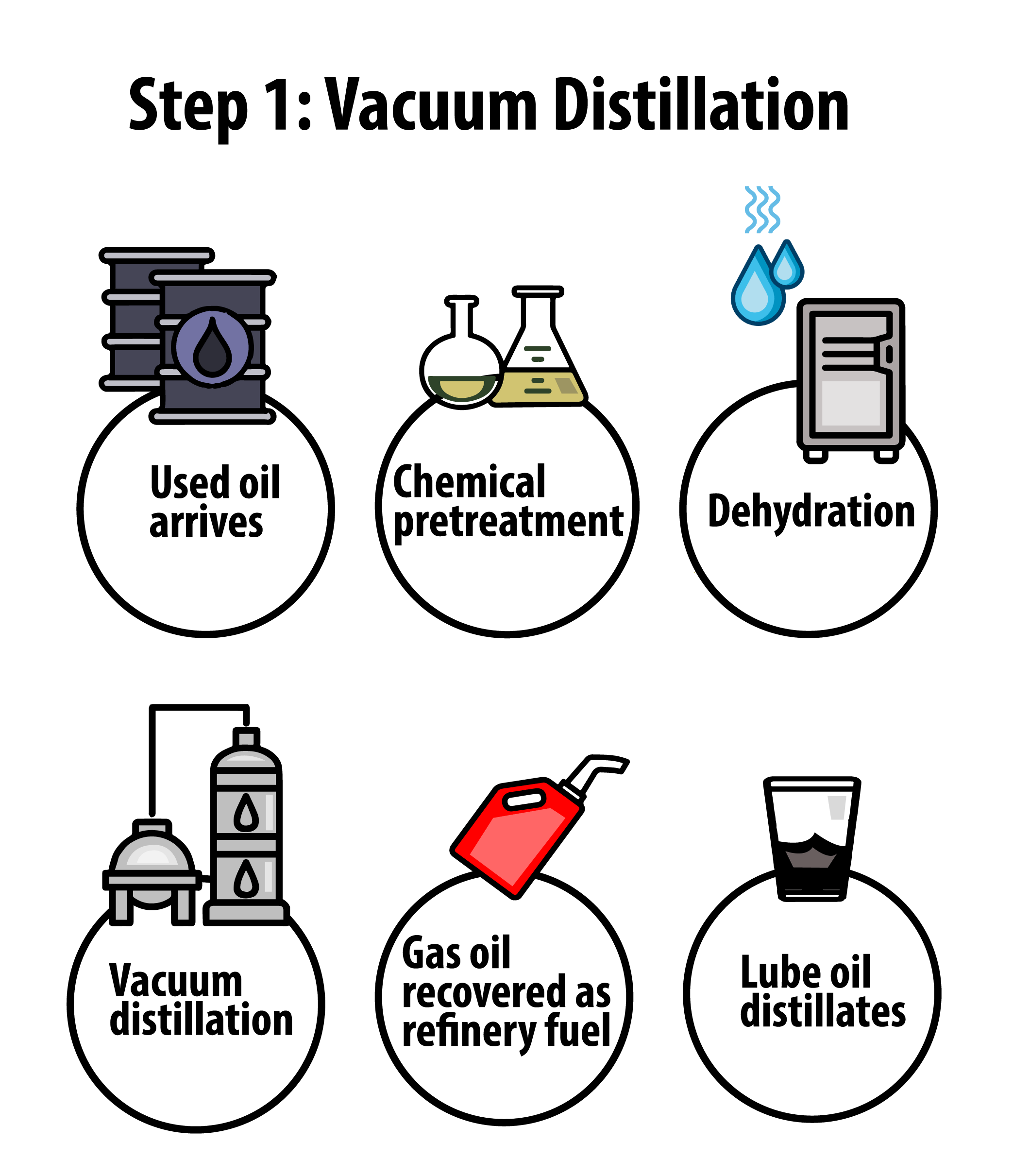

Step 1: Vacuum Distillation

- Used oil arrives. Inappropriate feedstocks are rejected.

- Chemical pretreatment.

- Dehydration. Water steam is cooled and discharged to municipal sewage treatment.

- Vacuum distillation.

-

- Asphalt flux is stripped off the bottom and sold for roofing materials.

- Gasoil is recovered as refinery fuel.

-

- Lube oil distillates result.

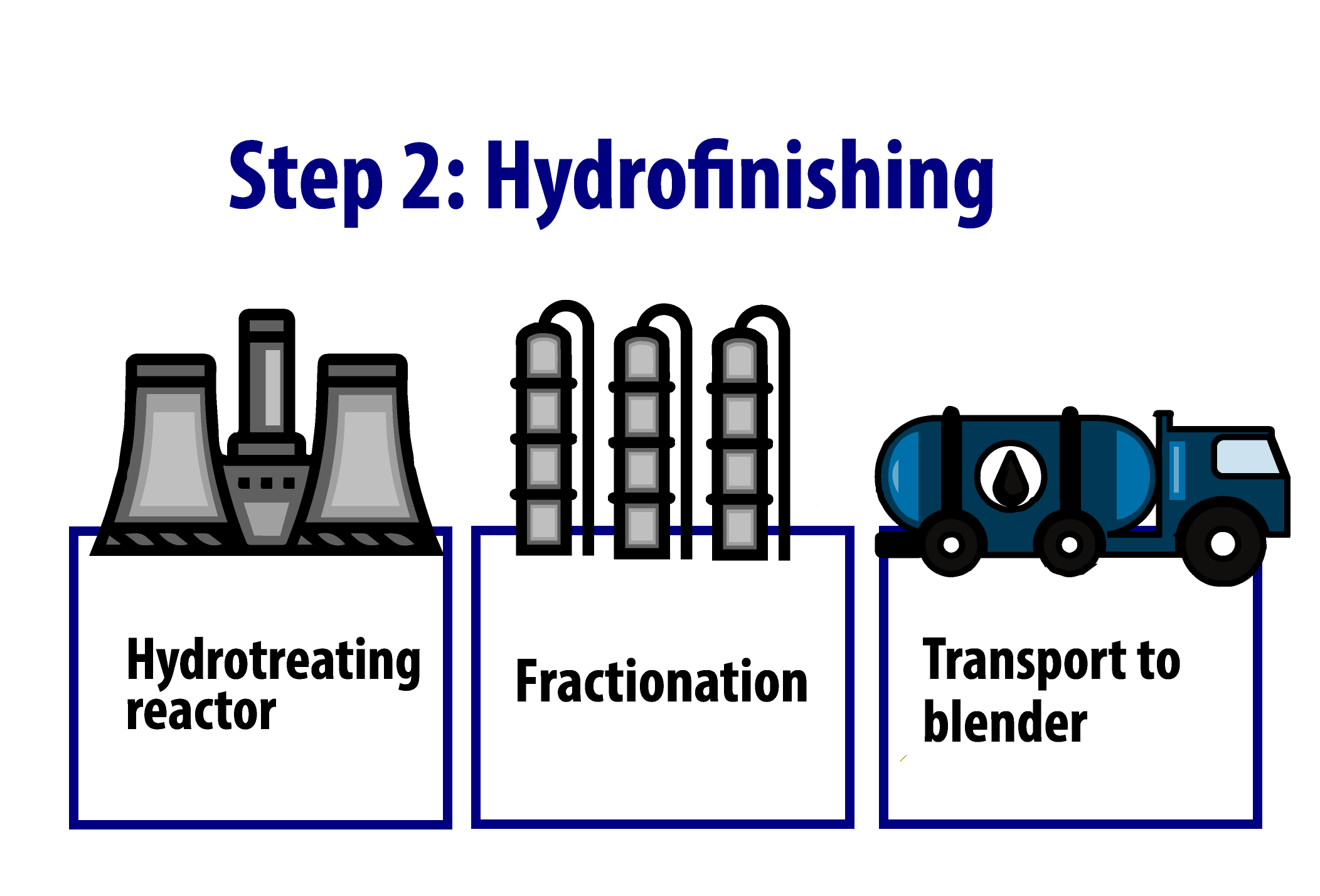

Step 2: Hydrofinishing

- Hydrotreating reactor.

- Fractionation results in 100-neutral base oil and 300-neutral base oil.

- Transport to blender to make into finished lubricants.

Myths about Rerefined Oil

Myth: Jurisdictions may have long-term contracts for oil for their fleets, and are unable to switch easily.

Reality: Long-term contracts usually have exemptions for pilot projects and minor contract amendments that allow an initial change for part of the fleet to rerefined oil.

Myth: Jurisdictions must accept service from the lowest bidder on a contract, potentially excluding rerefined oil.

Reality: Managers can solve this with:

- A procurement ordinance

- A price preference

Myth: Fleet lessors do not have control over the type of oil used in their vehicles.

Reality: Fleet lessors have some control. They can:

- Take their business elsewhere if requirements are not met

- Tell the lease agents they will only work use rerefined oil.